PORTAPIVOT & ALUPROF PARTNER | SERVING belgium

We Don’t Just Install.

We Engineer the Envelope.

Most installers are box-movers. DAG Enterprise processes raw Aluprof & PortaPivot profiles in-house to guarantee millimetre-perfect alignment for passive houses and luxury renovations.

Currently booking for Spring 2026 installations.

The Four Ways a Standard Installer Will Fail You

01

Great Design Dies in Poor Execution

You meticulously planned every thermal bridge, shadow gap, and sightline. Why hand those plans to a “box-mover” who treats your passive house like a standard row house? One sloppy seal destroys your EPB score; one misalignment ruins the aesthetic. We don’t just install windows; we engineer the fit from the raw profile up.

02

Stop Betting Your Timeline on Factory Queues

Most installers are middlemen at the mercy of foreign production lines. If a frame arrives sized incorrectly, your site shuts down for 6 weeks. We process raw profiles right here in Flemish Brabant. If a renovation reveals a crooked wall, we adapt the frame in our workshop immediately. You get certainty, not excuses.

03

The End of the ‘Not My Fault’ Era

It is the architect’s nightmare: A leak occurs, and the finger-pointing begins. The installer blames the product; the manufacturer blames the installation. Meanwhile, your client looks at you. When you partner with DAG, you eliminate that gap. We process the material and place the glass. Total accountability resides with us.

04

The High Cost of the Lowest Bid

In luxury construction, ‘standard’ is a liability. Saving 10% on an installer who lacks technical depth often costs 200% in repairs when the condensation starts five years later. You aren’t just paying for aluminium; you are paying for the silence of a job done perfectly. Do not finance your contractor’s learning curve with your home.

We Call It The Certified Envelope Protocol™

Phase 01

We measure twice, model once, and never guess.

Complex renovations in Flemish Brabant rarely have straight walls or level floors. We don’t rely on basic measurements. We perform a forensic structural analysis of every opening to anticipate thermal bridges and load-bearing conflicts beforea single piece of aluminium is ordered. We solve the installation problems on paper, so we don’t face them on your construction site.

Phase 02

Precision processing, not ‘Box-Moving.‘

While competitors wait for finished windows to arrive from Poland or Germany, we take control. We import raw Aluprof and PortaPivot profiles and process them in our own workshop. This allows us to customise the assembly to the millimetre, ensuring that even the most intricate architectural details, from pivot hinges to minimalist frames, are executed with factory-level precision, customised for your specific project.

Phase 03

Just-in-time logistics.

We coordinate transport to align strictly with your site schedule, reducing the risk of glass breakage or profile damage caused by sitting on a chaotic construction site.

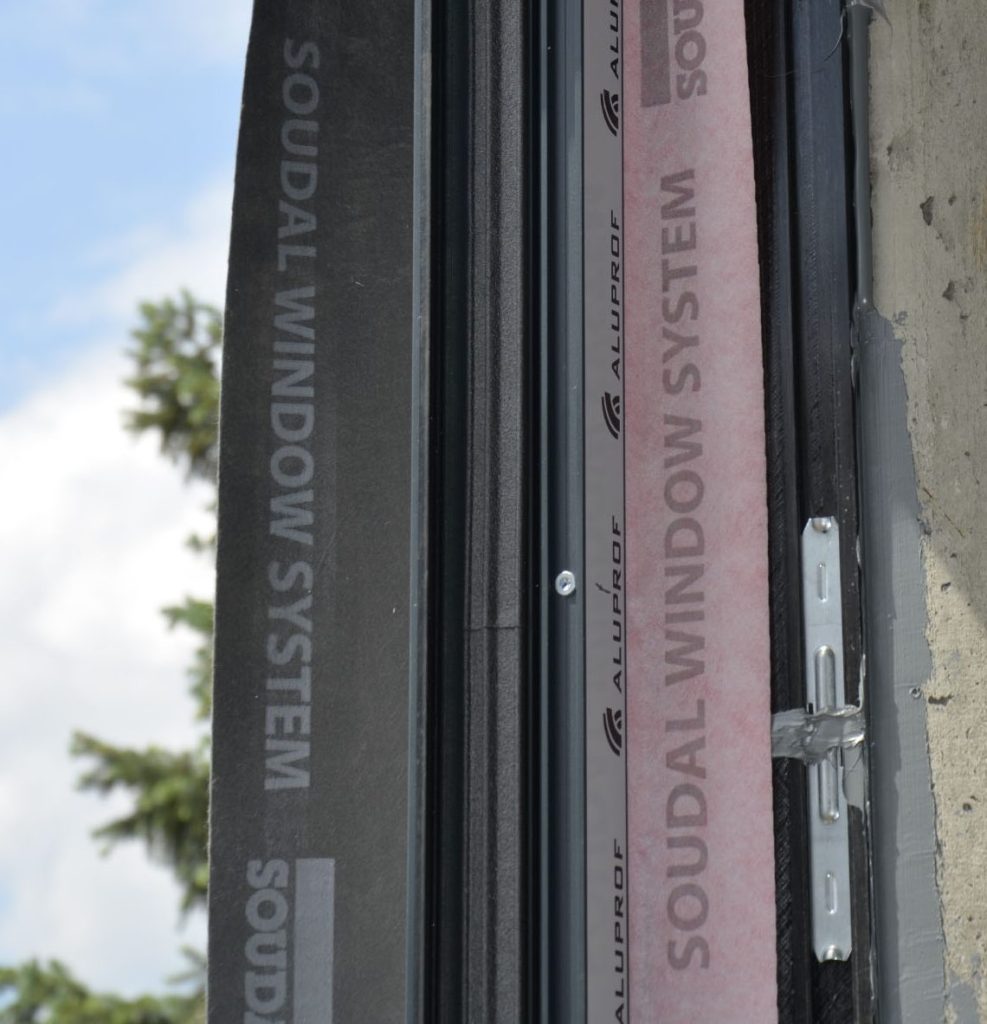

Phase 04

Where insulation meets isolation.

The best profile in the world fails if the installation is weak. We reject the ‘foam-only’ shortcut. Instead, we execute the rigorous 3-Layer Sealing Principle: vapour-tight internal taping for airtightness, high-density foam for thermal/acoustic insulation, and weather-resistant external membranes for rain protection. This ensures your project passes blower-door tests comfortably and remains mould-free for decades.

Phase 05

Validated performance, not just visual completion.

We don’t consider the job done when the glass is in. We perform a rigorous “stress test” on every moving element. We calibrate pivot mechanisms for effortless operation, verify seal compression, and walk you through the maintenance requirements. You receive a fully commissioned system that feels heavy in quality but light in operation.

Delivered Without Compromise.

The Double Pivot Statement

Passive Residence, Flemish Brabant

Redefining the open-plan concept, these custom-fabricated dual pivot doors utilise advanced stealth hinges to manage heavy glass loads with effortless operation. The black anodised aluminium frame creates a bold architectural graphic, offering flexible spatial division while maintaining light transmission and visual continuity across the living zones.

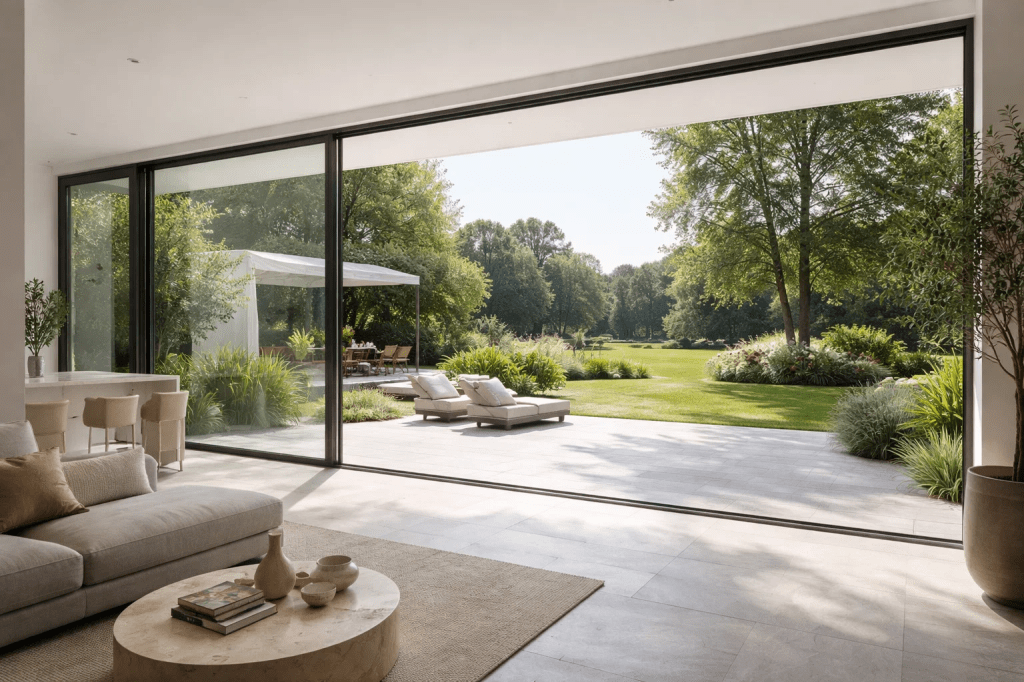

Seamless Frame Sliders

Passive Residence, Flemish Brabant

Achieving a zero-threshold connection, this thermally broken aluminium sliding system integrates flush with the floor. We engineered and installed oversized, triple-glazed units to meet passive house airtightness standards, ensuring uncompromised views and superior performance.

Acoustic Glass Partitioning

Passive Residence, Flemish Brabant

A showcase of precision fabrication and installation using custom-fabricated Aluprof minimalist profiles. This floor-to-ceiling acoustic glass partition defines the executive space with a sleek, black-framed aesthetic. The integration demands millimeter-perfect tolerance to achieve acoustic privacy without compromising the open-plan visual connectivity and light flow of the modern workspace.

The Modern Villa

Passive Residence, Flemish Brabant

A testament to architectural excellence, this luxury villa seamlessly blends indoor and outdoor living. We utilized advanced Aluprof systems to create oversized, floor-to-ceiling glass walls with minimal sight-lines, flooding the interior with natural light and providing unobstructed views of the pool and landscaped garden. This project exemplifies our capability to execute complex, high-end residential designs with precision and style.

The 360 Stealth Pivot

Passive Residence, Flemish Brabant

Custom-engineered using pivot door’s invisible hinge technology, this oversized glass partition creates a seamless spatial transition. The system supports heavy-duty glazing up to 150kg with a feather-light touch, allowing the door to float freely or hold position at 90°. The minimalist black anodised frame contrasts sharply with the raw concrete, delivering a functional art piece that anchors the interior design.

My biggest headache is the gap between delivery and installation. DAG Enterprise eliminated that. The truck arrived, the crane was ready, and the team was working within 30 minutes. No missing parts, no excuses. A rare experience in this market.

Marc V.

Project Manager

Mixed-Use Development, Brussels

Usually, I have to fight the installer to keep the profile sight-lines slim. They (DAG Enterprise) understood the vision immediately. They didn’t just install; they engineered the solution to make the design viable. The corner connections are flawless.

Jean-Paul D.

Senior Architect

Modernist Reno, Ghent

No Grey Areas. Just Clear Answers.

Because standard factory lines cannot handle the complexity of bespoke architecture. By importing raw profiles and processing them in our Flemish Brabant workshop, we control the tolerance to the millimeter. This allows us to adapt to irregular renovation walls and execute custom details (like floor-to-ceiling pivots) that mass-manufacturers simply refuse to touch.

You are not paying for the aluminium; you are paying for the envelope engineering. Standard installers operate on volume, often using “foam-and-go” tactics that fail thermal tests. We operate on precision. Our price includes the Certified Envelope Protocol™, forensic site surveying, and the 3-Layer Sealing guarantee. We don’t compete on the price of the window; we compete on the value of a risk-free installation.

Yes. We specialise in high-performance thermal envelopes. Because we use the 3-Layer Sealing Principle (vapour-tight internal taping, thermal insulation, and weather-proof external membranes), our installations consistently pass rigorous Blower-Door tests. We are happy to coordinate directly with your EPB reporter to ensure all nodes meet the required U-values.

It gives you certainty. Standard installers are at the mercy of foreign factory queues. If a glass pane breaks or a frame is sized wrong, you wait 6-8 weeks. Because we assemble locally, we can react to site changes immediately. We hold the stock, we own the machinery, and we control the schedule.

We believe in “System Integrity.” Aluprof offers the best balance of thermal efficiency and structural rigidity for European passive standards, while PortaPivot allows for architectural pivot doors that defy standard weight limits. We don’t mix-and-match cheaper generic parts; we use the authorized, engineered components that these systems were designed for.

We are. This is the primary benefit of the Architect-First model. Because we are both the manufacturer (processor) and the installer, there is no finger-pointing. You don’t have to chase a factory in Poland or a subcontractor who has disappeared. You call DAG Enterprise, and we resolve it.

We select projects based on complexity, not just size. If you need a standard white PVC window replaced, we are likely overqualified (and too expensive) for your needs. However, if you have a ‘small’ project that is technically demanding, such as a single, oversized pivot door or a complex glass extension, we are the right partner.